Mast Project Updates

Working with Melges, we have gotten some new extrusions completed to make a couple new mandrels for fabricating A Scow carbon masts. We have recently transported them to the manufacturer in Massachusetts for further work to get them ready for production. Once that work is complete, we will want to place some orders to get production jump-started again. Your input and ideas are welcome as to how we can finance these initial orders.

But wait, there’s more…

In other A fleet news, our boat builder, Melges Performance Sailboats of Zenda, WI recently approached your Commodore and Executive Director with two ideas for improvements to our boats. Melges CEO, Harry Melges III presented the ideas for discussion, with the stated intent “to make A Scows easier to sail and more funâ€. Neither of the ideas require any changes to our fleet scantling rules, so they do not fall under our existing procedures for experimentation.

Â

Self-Tacking Jib

One idea, the use of a self-tacking jib, is already in use by several boats and everyone who has this rig reports they work great and they can’t believe this has not caught on with the rest of us. Melges, through North Sails, can already deliver the smaller jib required for this update. The hardware needed to make this change still needs to be spec’d out and total cost for this conversion has not yet been determined.

Â

Spinnaker Launcher System

This second idea is one that many of us have been thinking about ever since the E Scow was successfully retrofitted with a spinnaker launch system. Harry reported that he had come up with a design for an A Scow system, and one boat approached him asking for a retrofit. As there was nothing in the rules to prevent use of a system like this, and seeing what this improvement did to expand the popularity of the E Scow, we agreed he should give it a try and see if it could be perfected. There is no guarantee this will work on the A Scow given the size of the spinnaker. And of course, it would be quite difficult to switch spinnakers mid-race as we sometimes do should conditions change.

Â

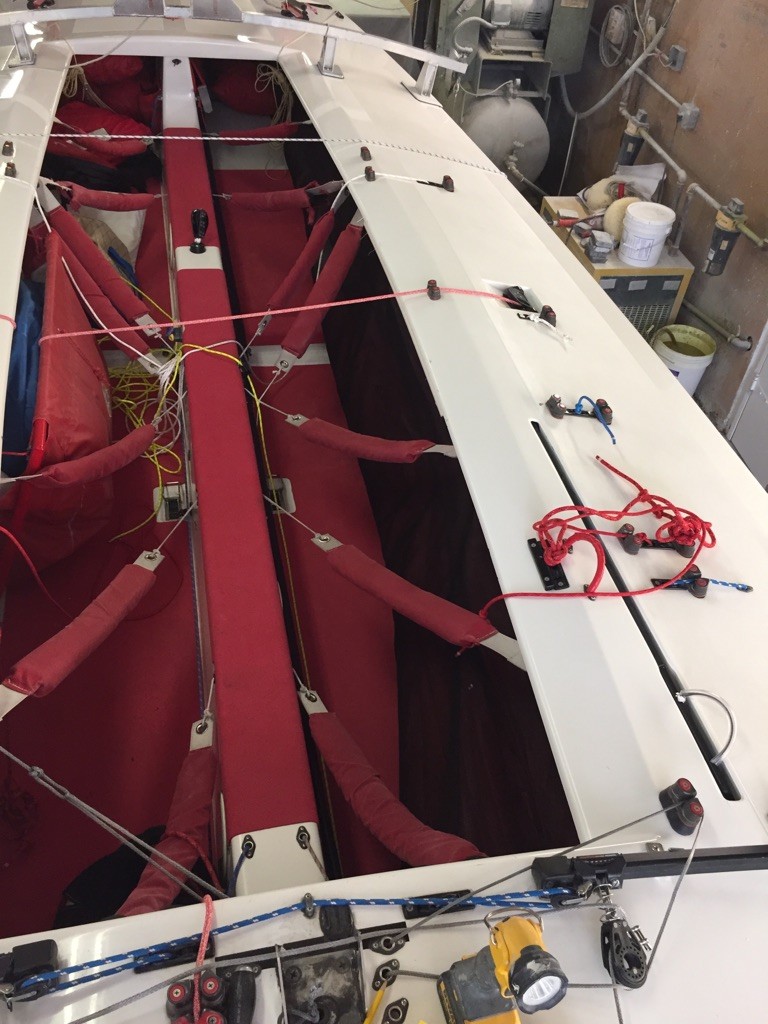

At this time, Harry is using the same deck mold as the E Scow retrofit, and a similar port-side long “sock†to stow the spinnaker. He has already commenced cutting deck holes and seeing if it might work – sea trials are probably underway as of this writing. The cost of materials for this retrofit will likely be more than for the E Scow, particularly if the deck mold needs to be redone in a larger size. Not surprisingly, labor to do the A Scow retrofit will be longer than on the E. Adding a patch to a spinnaker should be of nominal cost. It’s safe to say that this is still in the invention stage and may take a while to perfect, but we wanted to give everyone the heads up on it.

We will be eager to see the launcher in action at the ILYA Championship Regatta at Geneva. Our hope is that these affordable, and relatively easy changes to the A Scow will make the boat even more fun and much simpler to sail, which should help us bring in a few new boats to the fleet. By the way, there are several really nice used boats on the market right now, so take a look at our website for more details.

Sent to all NCASA members via email on August 8, 2017. If you missed it, join our email list here.